Experience

AT Dev Inc Internship

I had the incredible opportunity to work as a Robotics Engineering Intern at AT Dev Inc, a Los Angeles-based startup focusing on developing biomechanics solutions. My primary project involved developing and prototyping assistive technology for individuals with physical disabilities and those requiring post-surgical rehabilitation. I utilized my skills in CAD design using Solidworks and hands-on machining techniques with CNC Mills, Bandsaws, Drill Presses, and 3D scanning technology to create a leg brace featuring an innovative fastening system that I designed and implemented. This experience not only allowed me to apply my technical skills to real-world challenges but also provided valuable insights into the operation of a startup, the opportunity to interact with investors, and helped reinforce my passion of using robotics and engineering to improve people's lives.

(Limited information due to NDA)

As part of the Baja SAE competition team, I work on designing and fabricating an off-road vehicle that competes against other universities in rigorous events and endurance races. Through Solidworks FEA analysis, I redesigned the chassis to improve manufacturability and driver ergonomics. My responsibilities include optimizing the chassis design while communicating with other subteams to find the ideal design and manufacturing with TIG welding techniques and CNC machining. After demonstrating strong technical capabilities and leadership skills during my first semester, I was promoted to Chassis Lead, where I now oversee critical design decisions and collaborate with team members to ensure our vehicle meets competition standards. This role has strengthened my expertise in analysis, manufacturing processes, and team leadership while working under deadlines and competition requirements.

Baja SAE Team Member and Chassis Lead

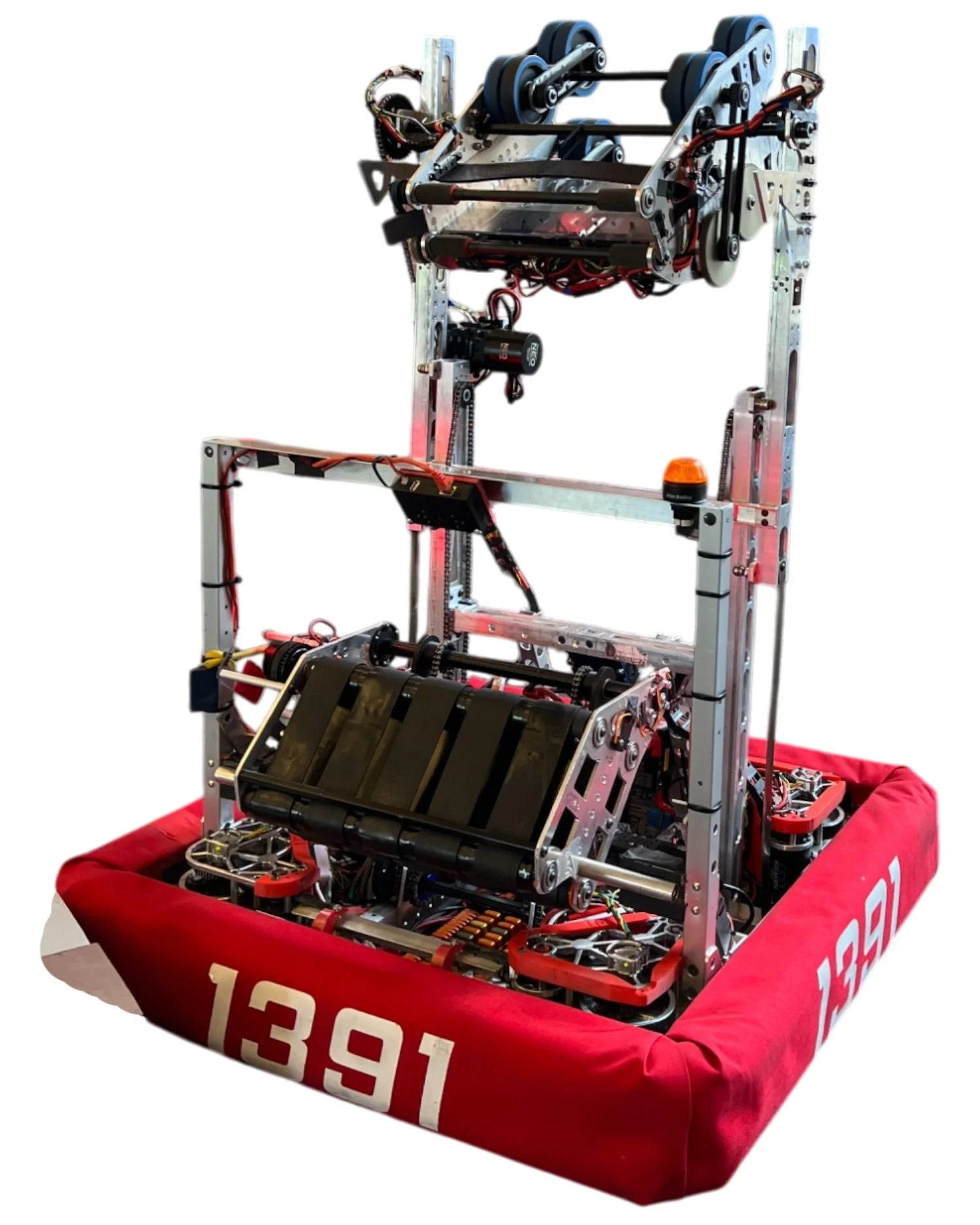

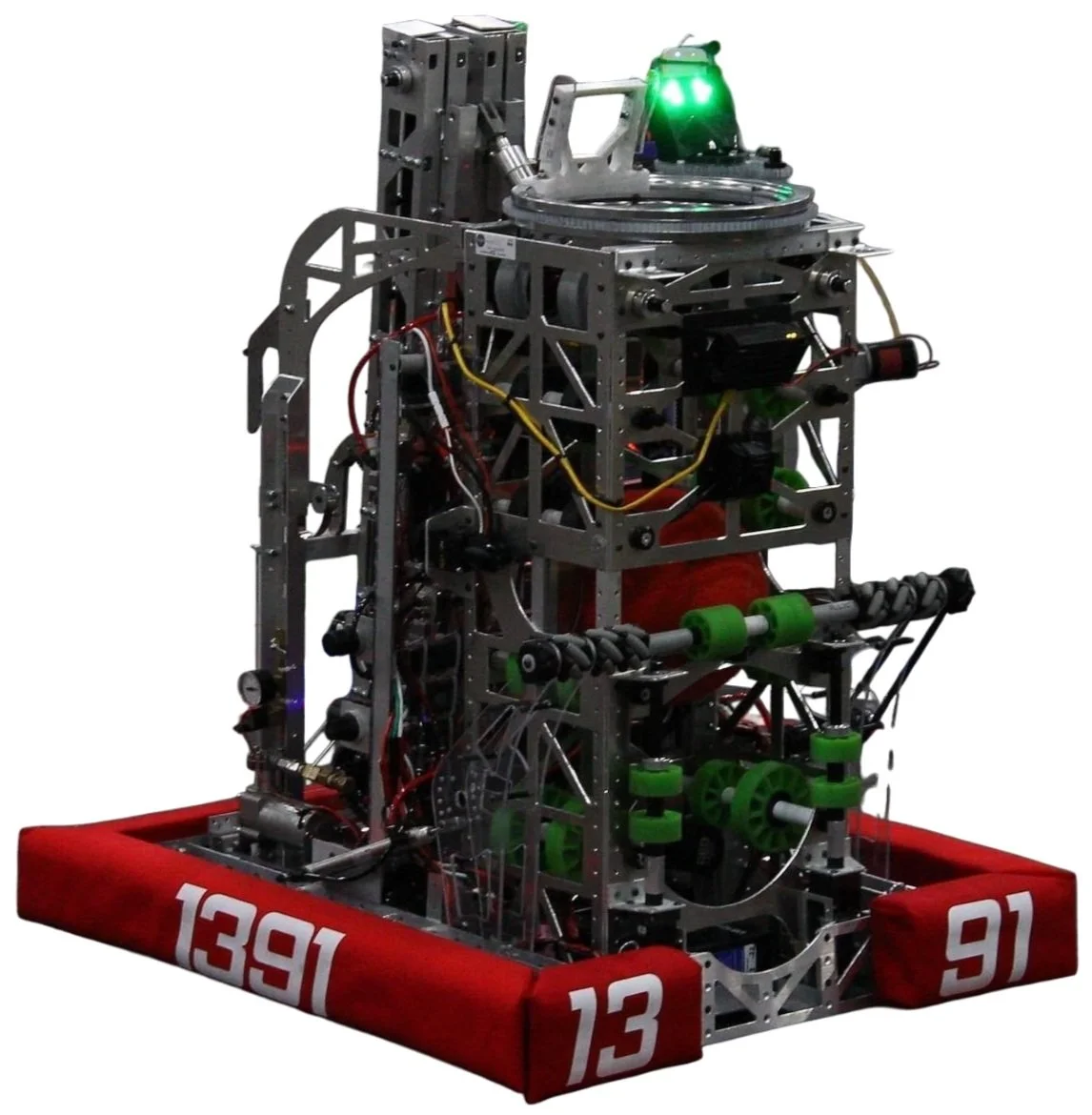

FRC Team 1391 Team Captain, Lead Builder, Operator and FTC Coach

On the FIRST Robotics Competition (FRC) team, I designed and manufactured competition robots using CAD software, CNC machines, lathes, mills, and various fabrication tools. As team captain, lead builder and operator, I developed mechanical systems including multi-stage climbing mechanisms, automated shooting systems, and precise intake systems. Through prototyping and testing, I optimized our robots' performance for maximum reliability and efficiency during competitions. I operated the robot during matches, helping lead our team to three consecutive World Championship appearances in Texas where we ranked in the top 3% globally. Our technical innovations and engineering documentation earned multiple awards including Engineering Excellence, Quality, and Autonomous awards, while also securing a District Championship Finalist position and Competition Winner title. Additionally, I mentored our school's FTC robotics team, teaching CAD design, manufacturing skills, and competition strategy to newer members.

Astara Data and Computer Science Intern

At Astara, a global mobility provider that helps companies optimize their vehicle fleets, I developed Python data analysis tools and automation solutions to improve business efficiency. Created web scraping scripts to monitor over 1000 competitors' prices, enabling real-time market analysis and strategic decision-making. By automating the company's reporting system, I reduced weekly report preparation time by over 90%, streamlining data processing and analysis workflows. The tools I developed continue to provide valuable competitive insights and operational efficiency improvements for the business.

(Limited information due to NDA)